Material

Handle die-cast zinc DIN EN 12844.

Steel parts stainless steel 1.4305.

Version

Handle plastic-coated or high-gloss trivalent passivated

Steel parts bright.

Axial needle bearing with hardened and ground thrust washer.

Steel parts bright.

Axial needle bearing with hardened and ground thrust washer.

Show more

Show less

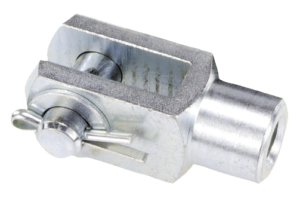

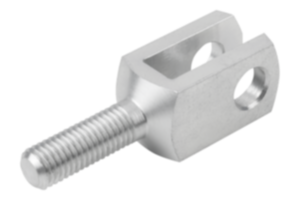

Clamping levers, zinc with external thread and clamping force intensifier, satin finish

from

kr283.91

plus sales tax

plus shipping costs

Clamping levers, zinc with external thread and clamping force intensifier, matt textured

from

kr283.91

plus sales tax

plus shipping costs

Clamping levers, zinc with external thread and clamping force intensifier, high-gloss chromed

from

kr283.91

plus sales tax

plus shipping costs

Description

Product description

By using clamping levers with integrated clamping force intensifier, the clamping force can be increased by up to 75% compared to standard clamping levers.

Furthermore, this product can also be used by persons with limited hand strength (e.g. in rehabilitation) to achieve comparable clamping forces with less effort. Less effort is also needed to loosen the clamping lever.

The increase in clamping force is achieved by the integral needle roller thrust bearing, which generates very low surface friction on a rigid contact surface during clamping. The hardened thrust washers are designed for high clamping forces and the bearing with its high load rating guarantees a long service life.

The clamped component is permanently protected by the large, stationary contact surface. A washer is no longer required.

Due to the modular construction many special designs are available.

Furthermore, this product can also be used by persons with limited hand strength (e.g. in rehabilitation) to achieve comparable clamping forces with less effort. Less effort is also needed to loosen the clamping lever.

The increase in clamping force is achieved by the integral needle roller thrust bearing, which generates very low surface friction on a rigid contact surface during clamping. The hardened thrust washers are designed for high clamping forces and the bearing with its high load rating guarantees a long service life.

The clamped component is permanently protected by the large, stationary contact surface. A washer is no longer required.

Due to the modular construction many special designs are available.

Material

Handle die-cast zinc DIN EN 12844.

Steel parts stainless steel 1.4305.

Version

Handle plastic-coated or high-gloss trivalent passivated

Steel parts bright.

Axial needle bearing with hardened and ground thrust washer.

Steel parts bright.

Axial needle bearing with hardened and ground thrust washer.

Method of operation

In the default position, the handle is engaged with the threaded insert through a toothed ring. By lifting the handle, it can be repositioned and re-engaged in the toothed ring by spring force.

Application

Machine, equipment and plant construction, rehabilitation sector.

Assembly

The screw-in depth must be at least 2 x the thread diameter and the thread should be lubricated lightly during installation.

Advantages

Significant increase of the clamping force with the same tightening torque.

High quality axial needle bearing with high load rating and long service life.

The component surface is protected by the stationary lower ring.

High quality axial needle bearing with high load rating and long service life.

The component surface is protected by the stationary lower ring.

On request

Other colours and thread lengths.

Drawing reference

1) flat point DIN EN ISO 4753