Material

Carbon steel.

Version

Contact faces hardened and ground.

Show more

Show less

Description

Material

Carbon steel.

Version

Contact faces hardened and ground.

Note

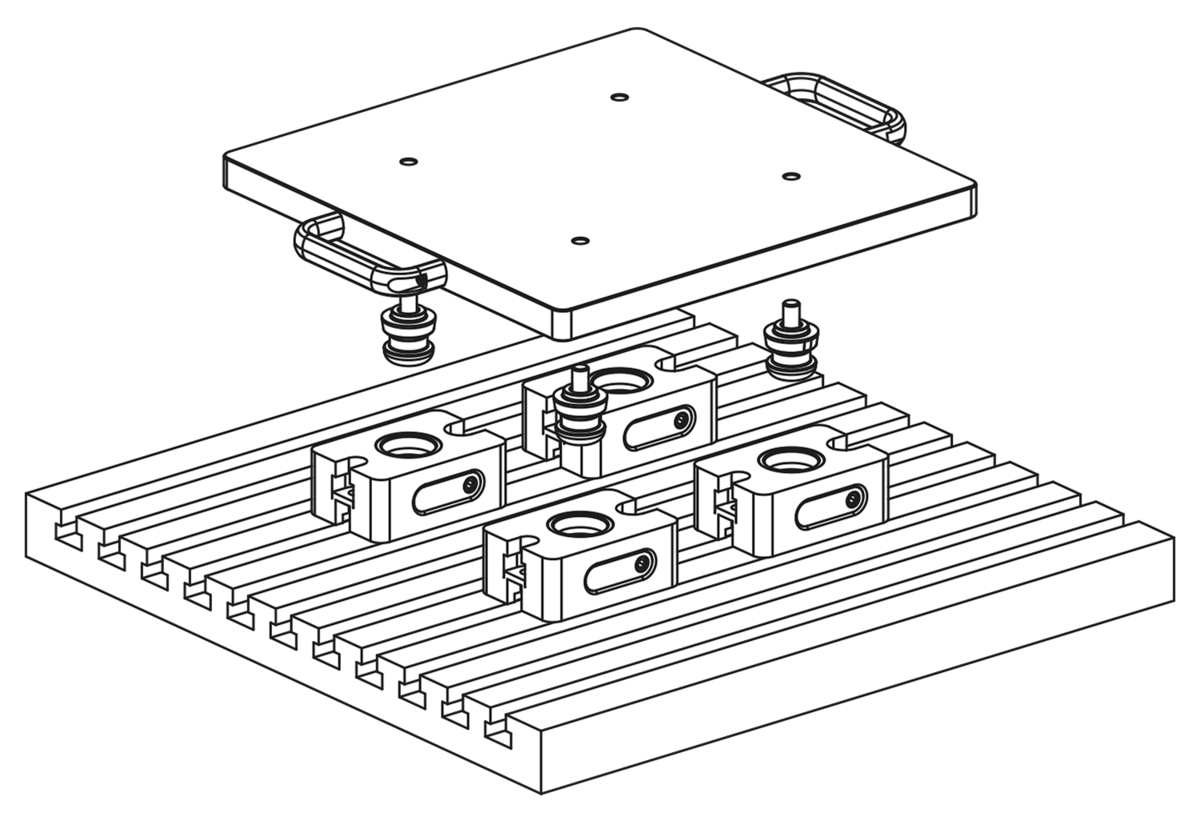

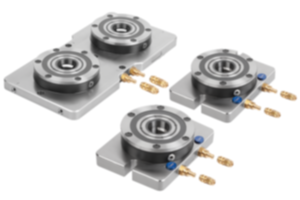

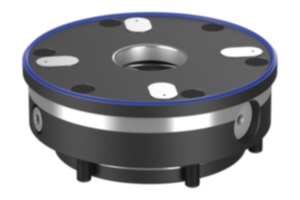

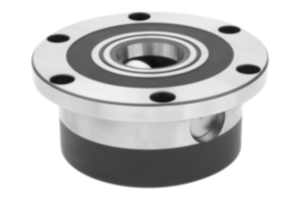

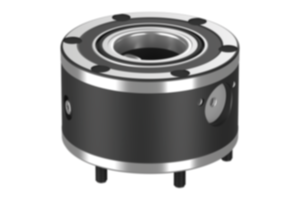

UNILOCK manual clamping modules can be adapted directly to machine tables with grid holes or T-slots, and to grid hole subplates with 50 mm grid spacing system size M12/M16.

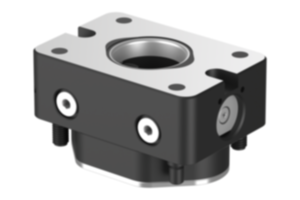

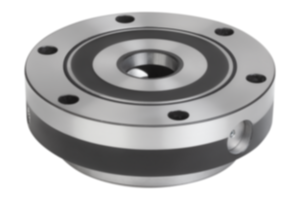

The UNILOCK manual clamping module H50 is particularly suitable for machines with reduced Z travel. The low installation height of the manual clamping module facilitates full utilisation of the Z travel.

The UNILOCK manual clamping module H50 can be mounted in any position.

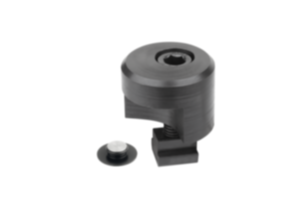

The following clamping forces are possible with the UNILOCK clamping pin in conjunction with M10, M12, M16 fastening screws:

- Clamping force (M10) 35,000 N

- Clamping force (M12) 50,000 N

- Clamping force (M16) 75,000 N

Clamping force with DIN EN ISO 4762 -12.9 cap screws.

Clamping pins may only be clamped in conjunction with a mounted interchangeable unit in the clamping module.

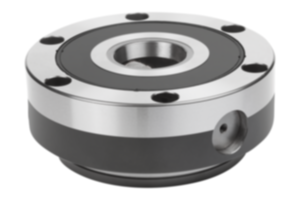

The UNILOCK manual clamping module can be fastened using DIN EN ISO 4762 -10.9 M12 or M16 cap screws.

The positioning of the UNILOCK manual clamping modules can be carried out using the two alignment holes D1 or the central alignment hole D.

In addition, there are two positioning holes B1 in the UNILOCK manual clamping modules for aligning interchangeable fixtures on the support surface.

The UNILOCK manual clamping module H50 is particularly suitable for machines with reduced Z travel. The low installation height of the manual clamping module facilitates full utilisation of the Z travel.

The UNILOCK manual clamping module H50 can be mounted in any position.

The following clamping forces are possible with the UNILOCK clamping pin in conjunction with M10, M12, M16 fastening screws:

- Clamping force (M10) 35,000 N

- Clamping force (M12) 50,000 N

- Clamping force (M16) 75,000 N

Clamping force with DIN EN ISO 4762 -12.9 cap screws.

Clamping pins may only be clamped in conjunction with a mounted interchangeable unit in the clamping module.

The UNILOCK manual clamping module can be fastened using DIN EN ISO 4762 -10.9 M12 or M16 cap screws.

The positioning of the UNILOCK manual clamping modules can be carried out using the two alignment holes D1 or the central alignment hole D.

In addition, there are two positioning holes B1 in the UNILOCK manual clamping modules for aligning interchangeable fixtures on the support surface.

Technical Data

Max. operating torque: 15 Nm.

Max. retraction force: 15 Nm.

Repeat accuracy ≤0.005 mm

Max. retraction force: 15 Nm.

Repeat accuracy ≤0.005 mm

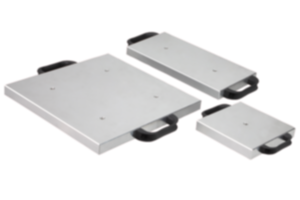

Scope of delivery

1 manual clamping module incl. fastening accessories.

Important note on downloading CAD models

You must log in before you can download our CAD models. If you have not yet created an account, please register under "My account" (right-hand side of the screen) and follow the instructions.